Lab. Global Plant Material Science

■Disciplines : Field of Specialty, Plant Material Science

TEL : +81 3 5841 5246

FAX : +81 3 5841 5246

E-mail

2008:Associate Professor, Department of Global Agricultural Sciences, Graduate School of Agricultural and Life Sciences/Faculty of Agriculture, the University of Tokyo

1997:Research Assistant, Biomaterials Sciences, Graduate School of Agricultural and Life Sciences/Faculty of Agriculture, the University of Tokyo

1997:Ph.D., Biomaterials Sciences, Graduate School of Agricultural and Life Sciences, the University of Tokyo

1992:B.S., Department of Forest Products Research, Faculty of Agriculture, Kyoto University

1996-1997:Research Fellowship, Japan Society for the Promotion of Science

1995-1996:Chercheur Associe au CNRS, Centre des Etudes sur le Macromoleculeur vegetales

Interest has been growing for some time in the use of plant materials as renewable resources. These plant materials have supported civilization in the form of materials used in construction and daily life, as well as for energy, for several thousand years of history. I hope to examine what technology with what characteristics was used in the past, and use modern methods to discover a separate aspect of plant materials. I want to find the potential for the use of unused plants that are abundant in Southeast Asia as new materials. I am also seeking methods to use as materials the characteristics of plant structure with their clever material design resulting from the long process of evolution and survival in the environment.

(1) Converting Unused Plant Biomass To Carbon Material

About one-fourth of plants after the reduction of water consist of carbon. Carbon materials are essential for industry, including adsorbents that help remove impurities from the air and water, battery materials, and rubber productfillers, most of these products are manufactured by using fossil resources. My research aims to expand the range of carbon materials, such as the unused plant biomass that is abundant in Southeast Asia, and discover new material technology suitable for converting them into materials.

• Reducing Energy in Process

Converting plants to carbon materials requires thermolysis by shutting off the oxygen to prevent them from burning, and then removing the hydrogen and oxygen as gases. Generally, temperatures of 600 - 2700 C are required, depending on the objective. I am involved in the conversion of carbon materials using microwaves (see #1 in Primary Papers) and catalysts to use less energy in the process.

• The Application of Gaseous Phase Carbonization

In the process of plant carbonization, in general, about half of the carbon is lost in the gaseous phase with hydrogen and oxygen as CH4, CO, and CO2. I am involved with the research to deposit the carbon from the thermolysis gas in the solid phase, and extend the gaseous phase as carbon materials with high regularity (see #10, Primary Papers). In the conventional process of creating charcoal, the structural history of the cell walls has an effect because it is solid phase carbonization. It is difficult to obtain material with orientation regularity and crystallinity.

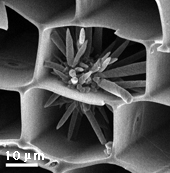

Fig. 1

In "gaseous phase carbonization", that deposits the once-gasified carbon in the solid phase, it is possible to create many types of carbon material by using different "seed crystals" and "templates". Of these, the result obtained by heating at 2000 C wood and bamboo containing trace amount of silicon, then the gaseous phase carbonizing of the thermolysis gas derived from cell walls into a carbon resource is known as "cone-shaped graphitic whiskers" (Fig. 1).

Fig. 2

The silicon carbide crystals generated at high temperatures works as a template, and the carbon hexagonal plane accumulates and elongates into a conical shape. This can be observed with a high-resolution transmission electron microscope (HRTEM) (Fig. 2).

I am attempting to make functional materials using the highly active carbon hexagonal plane edge of the whisker surface, the magnetic field orientation and the birefringent property that originates in the structural regularity.

• The Creation of Carbon Materials Utilizing Plant Characteristics

In the gaseous phase carbonization noted above, cellular structure in the µm order performed the role of efficiently storing the small volume of gas created by thermolysis and causing solid phase precipitation, in which the cell functioned as a microsized cell reactor (see #10 in Primary Papers). Focusing on the cell wall itself, it consists of minute cellulose fibers (nanofibers). Separating this into the constituent units enables their use as nanomaterials. Removing the cellulose from the cell walls results in the remainder of about half, with the multiple constituent elements including lignin and hemicellulose. Consequently, the carbonized matter derived from plant materials has a unique disordered structure not seen in carbonized matter derived from oil. Some of these may operate effectively for adsorption selectivity.

The trace amount of inorganic elements in plant cells has the potential as a catalyst in carbonization. My objective is to offer a carbonization technology suited to the composition of plant material, and carbon materials utilizing the structural characteristics of plants as living things.

(2) An elucidation of the microscopic structure and physical characteristics of plant material

I am searching for a new method to understand the mechanism of wood cohesion (which component of wood combine and in what kind of bond to aggregate). As one method, I have begun the dynamic measurement of the infrared and Raman spectrums for materials in a state of tension. When the material is tensed, the individual atomic bonds that are part of the material are also pulled. Differences in the distortion of the individual atomic bonds are created due to how the stress is allocated.

Until now, in natural macromolecular material with high crystallinity, we have apprehended this by the changes in the infrared and Raman spectrums. (see #2 in Primary Papers). It has been discovered that this method is also applicable to wood (see #3 in Primary Papers).

I hope to identify how the internal bonded water state of plant materials and changes in the quality of the material over time affect the mechanical characteristics in microscopic areas at the µm level. It is possible that these findings will provide hints for diagnoses of the durability of wood materials used for long periods and for considerations of forecasting their destruction.

(3) Research into the plant materials used in historical structures: An elucidation of the changes in physical properties resulting from the growth environment, harvesting methods, and the passage of time, and those mechanisms.

There is a method for building the roofs of traditional structures in Japan called "hiwadabuki". It is an ancient technique for thatching roofs by peeling off the bark of living Japenese cypress trees. Tree growth is still possible if the cambium directly underneath is not harmed when the bark is pulled off. This method of pulling off the bark multiple times and letting it grow back is similar to cork cultivation in the West.

As a specific example, we can interpret the oral testimony of traditional craftsmen who say that the regenerated bark is of better quality than the original bark. I am conducting research to determine how the regenerated bark fulfills the demands required of roofing material (2011 graduation thesis below) and whether the repeated peeling of the bark changes the quality of the Japanese cypress wood material (Saito, et al., 2008). Also, in connection with (2), I am conducting research into the changes over time in old wood used for several centuries (Morinobu, 2010 graduation thesis).

Through this research, I hope to identify the demand and performance of wood as well as plant material required for the preservation of structures that have been necessary for cultural assets. I also hope this will be of service for the continued maintenance and repair of historical structures by clarifying the conditions for securing stable resource supply.

1. Yukie Saito, Masatoshi Sato, Carbonaceous structural changes of wood induced by microwave irradiation, Holzforschung, 66, 85-92, 2012.

2. Yukie Saito, Tadahisa Iwata, Characterization of hydroxyl groups of highly crystalline beta chitin under sta

tic tension detected by FT-IR, Carbohydrate Polymers, 87, 2154 -9, 2012.

3. Yukie Saito, Atomic-level strain sensing using FT- IR to determine the load-carrying groups of wood, ProLigno, 7(4), 3-10, 2011

4. R. Yudianti, H. Onggo, Sudirman, Y. Saito, T. Iwata, J. Azuma, Analysis of functional group sited on multi-wall carbon nanotube surface, Open Mat. Sci. J., 5, 230-5, 2011.

5. Yukie Saito, Kodai Kuwata, Kyoko Suzuki and Tsutomu Suzuki, Sulfuric Acid Intercalation and Exfoliation of Nano shell carbon from Ni-catalyzed wood char, Trans. Mat. Res. Soc. Jpn, 36, 425-8, 2011.

6. Rie Yamashita, Yukie Saito, Satoshi Sakuragawa, Molecular sieving behavior of wood charcoal: selective adsorption of toluene from a gas mixture containing alpha-pinene, J Wood Sci, 55, 446-52, 2009.

7. Kodai Kuwata, Yukie Saito, Satoshi Shida, Masamitsu Ohta, Intercalation of wood charcoal with sulfuric acid, J Wood Sci, 55, 154-8, 2009.

8. Tsutomu Suzuki, Hiroshi Matsuzaki, Kyoko Suzuki, Yukie Saito, Sei-ichi Yasui, High electroconductivity of wood char obtained by iron-catalyzed carbonization, Chem Let, 37, 798-9, 2008.

9. Ken Watanabe, Yukie Saito, Stavros Avramidis, Satoshi Shida, Non-destructive measurement of moisture distribution in wood during drying using digital X-ray microscopy, Drying Technology, 26, 590-5, 2008.

10. Yukie Saito, Takanori Arima, Features of vapor-grown cone-shaped graphitic whiskers deposited in the cavities of wood cells, Carbon, 45, 248-55, 2007.

11. Yukie Saito, Youtaro Tomotake, Satoshi Shida, Formation of a lamellar compound by reaction of acrylic acid crystallo-solvated in highly crystalline beta chitin, Biomacromolecules, 8, 1064-8 , 2007.